Fire Suppression Systems

EDT provides the technical knowledge to design adequate Fire Suppression Systems relative to your spray drying equipment. Fire suppression systems require strategic placement of fire nozzles for ample water deluge that will protect equipment in the case of fire. EDT liquid-activated fire suppression nozzles provide this deluge by utilizing a specially designed spray head that fully extend under liquid pressure during fire suppression system activation.

Our complete fire suppression system includes EDT liquid-activated fire suppression spray nozzles, dump valves, water valves, controls and installation. Dump valves in our fire suppression system provide an outlet for water drainage to prevent components from filling with water, which can damage the structural support of the component.

Fire Suppression Spray Nozzle

EDT’s fire suppression spray nozzle follows the same concept as our CIP Spray Nozzle. The fire nozzle is a retractable, liquid-activated design. Our specially designed spray head extends under liquid pressure and remains stationery providing constant water deluge as long as the system is activated. The fire suppression spray nozzle is constructed of stainless steel and is USDA Accepted for sanitary applications.

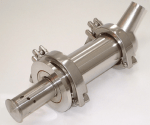

Sanitary Dump Valve

EDT sanitary dump valves are raising the standards in equipment protection. The dump valve will reduce and prevent structural damage to the building and drying equipment that is caused by equipment becoming weighted with water during fire suppression activation. EDT’s dump valve is specifically designed with a powerful long stroke to freely relieve components of dousing water, therefore, preventing water collection. Dump valves are placed on cyclones, baghouses, and other equipment that do not have an open discharge for water to escape. EDT’s sanitary dump valve is constructed of stainless steel in accordance to USDA guidelines.

Where Fire Protection is Needed